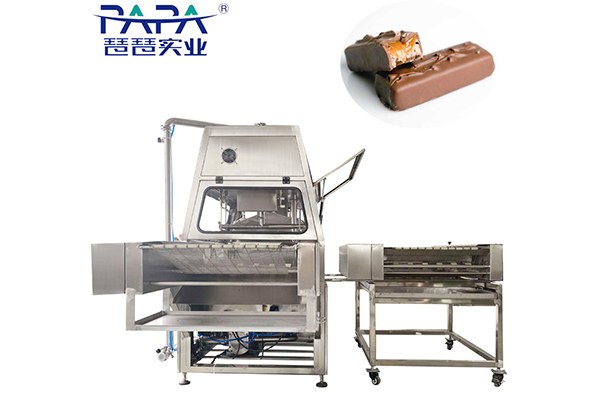

600mm width chocolate enrober for sale Australia

Short Description:

600mm width chocolate enrober for sale Australia wraps a layer of chocolate on the surface of the video, which is used in major food factories!

And it can also be docked with a multi-row protein bar extruder or an automatic cereal bar cutting machine to form a fully automatic production line.

Autotomatic chocolate enrobing line:

Chocolate Enrobing Line is to product chocolate on various food such as biscuit, wafers, egg rolls, cake pie and snacks etc to form variety of unique chocolate food.

Deploying automatic feed mechanism to improve production efficiency.

Deploying decorator to improve product quality ,decorate zigzags or stripes of different color on the surface of enrobed products.

Deploying spread material bodies to add tastes, to sprinkle sesame or peanut granulars on the enrobing products.

The machine can coat the whole surface or coat the single surface. The coating areas can be controlled by vibration and wind speed. Fan speed is uniform ,high quality for coating the chocolate .Coating surface is uniform, smooth and beautiful.

Features of chocolate covering machine:

1.The conveyor belt is provided with automatic correction device, the machine adopts touch screen, PLC control.

2.The cooling tunnel device is designed by us ,with air flow uniform and stability ,better than the normal equipments.

3.The machine is easy to clean ,the mesh uses pulling type ,it takes only about 20 minutes to clean the machine .

4.The machine can be designed for two double mesh belts to coat ,one side can be coated with white chocolate ,one black chocolate.

5.The length of the machine can be adjusted according to customer requirements.

6.The chocolate enrober can also coordinate with optional equipment,like decorator and granule sprinkler.1.Decorator:to decorate stripes or zigzags of different color on the surface of the products.2.Granule sprinkler:to sprinkle little granules on the surface of chocolate coated products.

Product detail pictures:

| Model | 400 | 600 | 900 | 1200 |

| Belt width(mm) | 400 | 600 | 900 | 1200 |

| Belt speed(m/min) | 1-10 | 1-10 | 1-10 | 1-10 |

| Cooling tunnel length(m) | 10 | 14 | 20 | 24 |

| Refrigerating unit(set) | 2 sets of 3P | 3 sets of 3P | 3 sets of 5P | 5 sets of 5P |

| Tunnel temperature(°C ) | 2-10 | 2-10 | 2-10 | 2-10 |