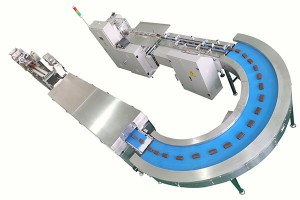

Chocolate coating machine for marshmallow

Short Description:

Chocolate coating machine for marshmallow is a special machine for coating various chocolate products such as cereals, wafers, cakes, biscuits, and wafer bars. Cooperate with chocolate cooling tunnel to make the finished product high quality and beautiful.

Chocolate coating machine for marshmallow

Chocolate coating machine for marshmallow Description:

Chocolate coating machine for marshmallow is to product chocolate on various food such as biscuit, wafers, egg rolls, cake pie and snacks etc to form variety of unique chocolate food.

Deploying automatic feed mechanism to improve production efficiency.

Deploying decorator to improve product quality ,decorate zigzags or stripes of different color on the surface of enrobing products.

Deploying spread material bodies to add tastes, to sprinkle sesame or peanut granulars on the enrobing products.

The chocolate coating machine for marshmallow can coat the whole surface or coat the single surface. The coating areas can be controlled by vibration and wind speed. Fan speed is uniform ,high quality for coating the chocolate .Coating surface is uniform, smooth and beautiful.

The conveyor belt is provided with automatic correction device, the machine adopts touch screen, PLC control.

The cooling tunnel device is designed by us ,with air flow uniform and stability ,better than the normal equipments.

The chocolate coating machine for marshmallow is easy to clean ,the mesh uses pulling type ,it takes only about 20 minutes to clean the machine .

The chocolate enrobing machine can be designed for two double mesh belts to coat ,one side can be coated with white chocolate ,one black chocolate.

The length of the chocolate coating machine can be adjusted according to customer requirements.

The video of chocolate coating machine for marshmallow

Our company

Shanghai PAPA Industrial Co.Ltd, established in 2004, is located near Shanghai Hongqiao and Pudong airport.Short distance, convenient for customers to visit the workshop. After more than 10 years of experience and technology accumulation, our company has first-class production base and R&D building, as well as a full set of processing equipment. In addition, we also have a group of senior enginners and technicians who design and improve the best machines according to the diiferent requirements of customers, and provide customers with test bases.

Product detail pictures:

| Model | 400 | 600 | 900 | 1200 |

| Belt width(mm) | 400 | 600 | 900 | 1200 |

| Belt speed(m/min) | 1-10 | 1-10 | 1-10 | 1-10 |

| Cooling tunnel length(m) | 10 | 14 | 20 | 24 |

| Refrigerating unit(set) | 2 | 3 | 4 | 5 |

| Tunnel temperature(°C ) | 2-10 | 2-10 | 2-10 | 2-10 |

| Total power(kw) | 12.1 | 20.8 | 23.8 | 27.8 |

| Weight(kg) | 2000 | 2450 | 3400 | 4100 |

| Dimension(mm) | 14200x950x1800 | 18200x1150x1800 | 24200x1450x1800 | 28250x1750x1800 |