Complete production line chocolate protein bar machinery packaging line

Short Description:

Turnkey project solution-chocolate protein bar and fully automatic packaging to reduce manual contact with products and form a fully automatic production line!

Complete production line chocolate protein bar machinery packaging line

Papa Machinery Equipment Co., LTD. is a manufacturer of a Complete production line chocolate protein bar machinery packaging line with well-equipped testing facilities and strong technical force. With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in Food Industry.

Description of chocolate protein bar production line:

Complete production line chocolate protein bar machinery packaging line is not only suitable for small-capacity enterprises but also can be used for large-capacity enterprises. The complete production line chocolate protein bar machinery packaging line is our newly designed machine according to customers' requirements of smaller size and low budget. Compared with other extruders, the volume is smaller and the efficiency is higher. Complete production line chocolate protein bar machinery packaging line is very suitable for making energy bars, nut bars, date bars, protein bars, coconut bars, fig bars, fruit bars and other bars. Wait. you deserved it!

Chocolate protein bar production line video:

Complete encrusting extruder for chocolate-coated date bar with two cooling tunnel

Snack bar display:

Protein bar

Fruit bar

Crackers

Coconut bar

Chocolate bar

Date bar

Introduction to Production Process

Most of the protein bars on the market are composed of protein powder, milk, peanut butter, crushed nuts, eggs, and other raw materials. These raw materials are poured into a mixer in a fixed proportion and mixed together

Pour the mixed raw materials into the machine hopper, and the size of the hopper can be customized according to customer requirements

The raw materials will extrude fine protein strips along the extrusion port, and then the cutting knife will cut them to form protein bars of consistent size. The width and height of the protein bars can be customized according to the customer's protein bar size

The protein bars will enter the chocolate coating machine along with the conveyor belt, and a thin layer of chocolate will be coated on the surface of the protein bars. Customers can also purchase two coating machines to connect together, so as to make two-color chocolate protein bars

If you want to quickly cool chocolate, or if you want to produce protein bars in the scorching summer, and the room temperature is too high to affect the cooling speed of chocolate, then you need purchase a cooling tunnel.

The cooled chocolate protein bars will enter the seasoning, and the seasoning will sequentially transport the protein bars to the packaging machine

The packaging machine is equipped with ink cartridges that can print the production date and number, and the final perfect chocolate protein bar is produced

Small protein bar machine

Small protein bar machine is our newly designed horizontal type single row extrusion machine according to customers’ requirement of smaller size and low budget. the small protein bar machine can make protein bar, date bar, fruit bar, energy bar, nutrition bar, power bar and so on. Small protein bar machine can be used to produce a soft mixture, hard mixture or sticky mixture bars. Small protein bar machine adopts horizontal double screw extrusion to ensure the smooth extrusion of dough to the rectifier.

Small chocolate enrobing machine

The automatic chocolate enrobing machine coats chocolate on various foods such as biscuits, wafers, egg rolls, cake pie, and snacks, etc.

The small chocolate enrobing machine can paint the whole surface or single face. The coating area can be controlled by vibration and wind speed. Fan speed uniform, high quality, suitable for coating chocolate. The coating surface is uniform, smooth and beautiful.

1.The cooling channel is equipped with an independent cooling device, special circulating air duct, and temperature regulating device.

Our company can achieve the best cooling process, thus providing the best quality of the product.

With the best cooling tunnel solution, your products can have a beautiful luster, excellent adhesion, and sweet consistency. By ensuring that your products have the highest cooling tunnel process, you can competitive edge and excellent products.

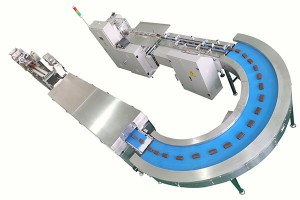

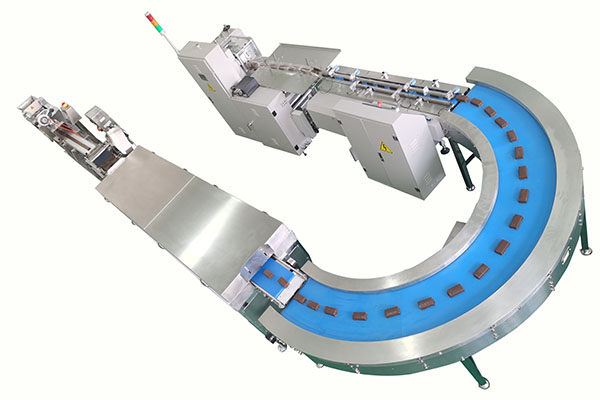

U turning conveyor

1.U turning conveyor can save a lot of production space.

2.It is easy to install and disassemble, high speed, efficient and safe.

3.Through the motor speed regulation can fully meet your production and demand.

4.Fully 304 stainless steel structure ensures stable and reliable operation of the machine.

Connecting conveyor

1.The main control circuit is controlled by a frequency converter and PLC touch screen, which provides a good man-machine interface.

2.The whole machine is controlled by a double frequency conversion range and the wide speed regulation range continues.

3.After setting the length of the packaging film and bag, the electronic eye with high sensitivity can automatically control and track the length Precision bag without manual adjustment.

4.The printer can be configured according to the user's needs to synchronize the printing of production date and batch number with the packing.

Our company

Shanghai PAPA Industrial Co.Ltd, established in 2014, is located near Shanghai Hongqiao and Pudong airport. Short distance, convenient for customers to visit the workshop. After more than 10 years of experience and technology accumulation, our company has a first-class production base and R&D building, as well as a full set of processing equipment. In addition, we also have a group of senior engineers and technicians who design and improve the best machines according to the different requirements of customers and provide customers with test bases.

Our service

PAPA industrial provides complete pre-sales and after-sales services for our encrusting machines, including customer inspection, customer learning, customer training, and guidance on installing and debugging the encrusting machine.

Certificates

Customer feedbacks

What skills you most during a purchase?

1.Do you have machine in stock?

Yes, we have! And we can delivery within 3 days.

2.Can you provide your local client information?

Yes, we can! Please contact us for more information!

3.What if your machine can not make our products?

Firstly, we provide trial test before order! Secondly, we promise full refoud if trial failed!

4.What if machine breaks down or not working properly!

We order 1 year warranty and lifetime serviice!

5.What if machine breaks down or not working proper?

Acquiring "durable year survey" of clients over decades, For specific data, please contact us!During warranty, free replacement! After warrant, online service or engineer dispatching!

Product detail pictures:

| Model | P307-1 |

| Output | 10-60pcs/min |

| Product weight | 10-250g |

| Power | 0.5kw |

| Voltage | 220V/380V |

| Dimension | 5500*2000*1680mm |

| Weight | 4500kg |