Europe style for Snack Food Making Line - Top Suppliers Caramel Or Chocolate Coating Popcorn Production Line|hot Air Puffing Popcorn Machine|puffed Popcorn Production Line – Papa

Short Description:

Europe style for Snack Food Making Line - Top Suppliers Caramel Or Chocolate Coating Popcorn Production Line|hot Air Puffing Popcorn Machine|puffed Popcorn Production Line – Papa Detail:

To be a result of ours specialty and repair consciousness, our corporation has won a good popularity amid consumers everywhere in the environment for Top Suppliers Caramel Or Chocolate Coating Popcorn Production Line|hot Air Puffing Popcorn Machine|puffed Popcorn Production Line, Our enterprise has already build a experienced, creative and responsible group to create consumers while using the multi-win principle.

To be a result of ours specialty and repair consciousness, our corporation has won a good popularity amid consumers everywhere in the environment for Hot Air Puffing Popcorn Machine, Popcorn Production Line, Puffed Popcorn Production Line, Our company has always insisted on the business principle of “Quality, Honest, and Customer First” by which we have won the trust of clients both from at home and abroad. If you are interested in our solutions, you should do not hesitate to contact us for further information.

Description

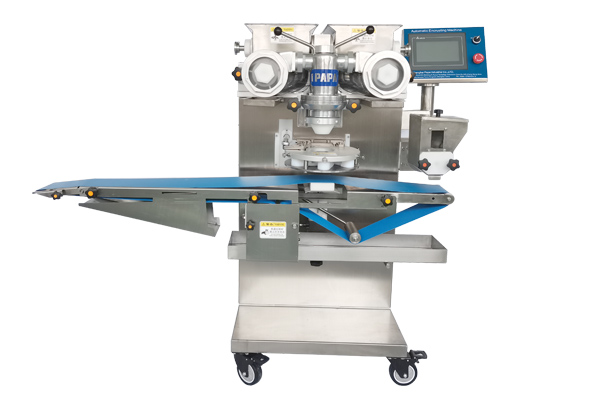

Chocolate Enrobing Line is to product chocolate on various food such as biscuit, wafers, egg rolls, cake pie and snacks etc to form variety of unique chocolate food.

Deploying automatic feed mechanism to improve production efficiency.

Deploying decorator to improve product quality ,decorate zigzags or stripes of different color on the surface of enrobed products.

Deploying spread material bodies to add tastes, to sprinkle sesame or peanut granulars on the enrobing products.

The machine can coat the whole surface or coat the single surface. The coating areas can be controlled by vibration and wind speed. Fan speed is uniform ,high quality for coating the chocolate .Coating surface is uniform, smooth and beautiful.

Features:

1.The conveyor belt is provided with automatic correction device, the machine adopts touch screen, PLC control.

2.The cooling tunnel device is designed by us ,with air flow uniform and stability ,better than the normal equipments.

3.The machine is easy to clean ,the mesh uses pulling type ,it takes only about 20 minutes to clean the machine .

4.The machine can be designed for two double mesh belts to coat ,one side can be coated with white chocolate ,one black chocolate.

5.The length of the machine can be adjusted according to customer requirements.

6.The chocolate enrober can also coordinate with optional equipment,like decorator and granule sprinkler.1.Decorator:to decorate stripes or zigzags of different color on the surface of the products.2.Granule sprinkler:to sprinkle little granules on the surface of chocolate coated products.

Product detail pictures:

Related Product Guide:

In Ireland, Milk Chocolate Reigns | Chocolate Machine Price

Former Ford Field chefs dip into chocolate business CRAINS-DETROIT-horizontal-red-wht CRAINS-DETROIT-horizontal-red-wht | Convection Oven Rotisserie

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for Europe style for Snack Food Making Line - Top Suppliers Caramel Or Chocolate Coating Popcorn Production Line|hot Air Puffing Popcorn Machine|puffed Popcorn Production Line – Papa, The product will supply to all over the world, such as: Istanbul , Denmark , Philadelphia , We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!