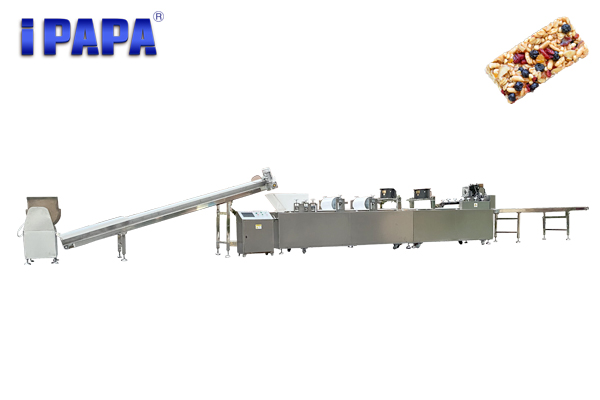

PAPA granola bar manufacturing process

Short Description:

Granola bar manufacturing process is the most mature product we sell. Granola bar manufacturing process is multi-functional and can produce various types of snack bars, such as cereal bars, cereal bars, granola bars, nut bars, etc. We have different models of granola bar manufacturing process for customers to choose according to different capacity requirements.

PAPA granola bar manufacturing process

Description:

Granola bar manufacturing process is our newly developed product in recent years. The PAPA cereal bar machine cost adopts advanced European technology and design, with high configuration and quality. The PAPA cereal bar machinery is multifunctional to make cereal bars, granola bars, energy bars, nuts bars, protein bars, nougat candy bars, muesli bars, nutrition bars, seed bars, rice bars, and so on.

Granola bar manufacturing process includes syrup cooking, storage, continuous mixing, material double rolling, tunnel cooling, longitudinal cutting, bar separator, guillotine cutting, conveyor.

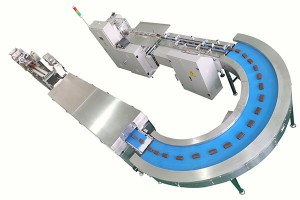

The granola bar manufacturing process can also coordinate with the chocolate enrobing machine, which can produce all kinds of chocolate enrobed bars.

Features:

1.The cereal bar machine is a fully automatic line with a PLC control system.

2.The cereal bar making machine adopts German technology with the highest performance.

3.The cereal bar production line is multifunctional,it can make cereal bar, nuts bar, seeds bar, energy bar, protein bar, etc.

4.The cereal bar maker can be perfectly connected with the chocolate enrobing line for making chocolate bars.

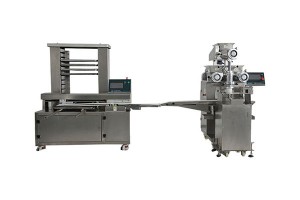

Cereal bar machine display:

What kinds of products can our automatic cereal bar production line make?

|

PAPA cereal bar machine cost video

Our company

Shanghai PAPA Industrial Co.Ltd, established in 2014, is located near Shanghai Hongqiao and Pudong airport. Short distance, convenient for customers to visit the workshop. After more than 10 years of experience and technology accumulation, our company has a first-class production base and R&D building, as well as a full set of processing equipment. In addition, we also have a group of senior engineers and technicians who design and improve the best machines according to the different requirements of customers and provide customers with test bases.

Our customer

PAPA industrial provides complete pre-sales and after-sales services for our encrusting machines, including customer inspection, customer learning, customer training, and guidance on installing and debugging the encrusting machine.

Product detail pictures:

| Model |

P401 | P402 | P403 |

| Capacity | 150-250KG | 250-350KG | 300-800KG |

| Power | 5KW | 5.5KW | 10KW |

| Voltage | 380V 3 phase | 380V 3 phase | 380V 3 phase |

| Dimension | 4800*920*1200mm | 6000*920*1200mm | 12000x1400x1300mm |

| Weight | 1200KG | 1500KG | 1800KG |

| Cooling type |

Fan cooling | Fan cooling | Refrigerator |